Dear customers ,Thanks for your coming, I am Alice, the international marketing manager of Baolai Packaging Co., Ltd. And I have been engaged in the flexible packaging bag industry since 2006 and have been committed to the research and customization of packaging bags.

The following is the professional knowledge about various composite packaging bags that I have summarized in my work for 9 years. I hope you will see it and be able to learn about packaging bags through this article. I hope to be able to help companies who want to make customized packaging bags but don’t know how to choose. I hope to make friends all over the world and invite you to come to our factory to guide work. I look forward to seeing you .

I guarantee in the name of God that the packaging bags we produce are absolutely food-grade materials, and they are tailor-made for you according to the products you are packaging. Our mission is to provide customers with the most perfect packaging bags. We have been working hard for this.

1, Vacuum Bag

The vacuum bag is to extract the air from the bag after packaging the product to reduce the contact between the product and the air. Therefore, the storage time is longer.

The material difference of the vacuum bag:

A. Nylon vacuum bag (Nylon+PE)

B. Polyester vacuum bag (PET+PE)

They are all transparent packaging bags, no difference can be seen on the surface,

The real difference between them is:

Nylon vacuum bags have longer storage time after packaging products, are not easy to leak, and have good puncture resistance. They are generally used to help grains, such as rice, millet, and beans.

The storage time of the polyester vacuum bag is relatively short, and it is easy to leak. It is not suitable for long-distance freight. Once it is dropped, it will leak air, and the vacuum effect will not be achieved.

C: Aluminum foil vacuum bags.

Aluminum foil packaging bags are expensive and have a better vacuum effect. They are generally used for packaging medicinal materials and some liquids. It has very good light resistance, and after aluminum foil and plastic are laminated, they will combine the common characteristics of aluminum foil and plastic, so as to achieve the effect that other packaging bags cannot achieve.

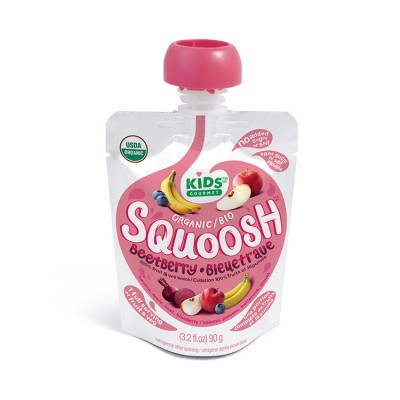

2, Spout Pouch

The spout pouches has one more suction nozzle than other bags. It is generally used to pack juice, puree, ketchup, water, etc. The following text will be my introduction to the spout pouch.

A: Transparent nozzle bag

A, two-layer transparent nozzle bag: PET+PE

B, two-layer transparent nozzle bag: Ny+PE,

C, three-layer transparent nozzle bag: PET+Ny+PE,

They are all transparent, even if we are expert in this field, we can not see the difference before pack .

The difference in transparency is that the nylon spout bag is stronger and airtight, while the three-layer nylon spout bag is the strongest, and of course the production cost is also the highest.

Aluminum foil spout pouch

A. Three-layer aluminum foil nozzle bag: PET+AL+PE, not strong and easy to rot. Our factory never produces this nozzle bag in order to save production costs. If a salesperson recommends this kind of nozzle bag to a customer, he will receive severe punishment from the company, so our quality is very guaranteed.

B, Four-layer pasteurization or hot-filling special packaging bag, PET+AL+Ny+PE,

C, high temperature cooking nozzle bag, PET+AL+Ny+RCPP, suitable for steam sterilization, the temperature is 105-121 degrees Celsius. The sterilization time is within 45 minutes.

- Stand up Pouch :

Stand up pouch have zipper stand up pouch and without zipper stand up pouch ,

If the standing bag with a zipper can be sealed multiple times, which is very convenient and very suitable for packaging snacks and products that are used multiple times.

The standing bag without zipper is best to be used up once after opening. If it cannot be used up at one time, it needs to be sealed with other products to avoid moisture.

Types of standing bags:

A, transparent standing bag:

PET+PE, (Shiny)

MOPP+PET+PE, (matte)

B, aluminized stand-up pouch (VMPET)

PET+VMPET+PE (Shiny)

MOPP+VMPET+PE (Matte)

C, Aluminum foil stand-up pouch

PET+AL+PE is the best moisture-proof and light-proof effect among all stand-up pouches.

4. Retort Pouch

Retort bags have the highest material and technical requirements among all packaging bags. There are transparent retort bags and aluminum foil retort bags. Among them, the aluminum foil retort bags have three layers of retort bags and four layers of retort bags.

A transparent cooking bag:

A, PA+RCPP

B, PET+PA+RCPP

2. Aluminum foil cooking bag:

A, PET+AL+RCPP, average quality, the highest cooking is 121 degrees Celsius, suitable for 100g products

B, PET+AL+Ny+RCPP, good quality, suitable for all products that need to be steamed.

5. Kraft paper packaging bag

We have now developed a kraft paper packaging bag for lectures, and the inner plastic is also a biodegradable material. It can be used to pack mobile phone chargers, data cables, underwear and other products.

Note: Although the retort pouch can be better sterilized and can be cooked at high temperature, many products are suitable for high-temperature retort pouches. High-temperature retort pouches can only be used after cooking at a high temperature above 100 degrees Celsius. Only after steaming above 100 degrees will it be stronger. The cooking materials that have not been steamed at high temperature are very brittle, easy to rot, and cannot be broken.

I hope my summary can give you a certain understanding and understanding of packaging materials. It doesn’t matter if you don’t understand, we will provide you with the most perfect packaging solution.

Post time: Jun-24-2021