For the Compostable biodegradable packaging bag ,They are new environmentally friendly material,Can pack dried food ,Solids, particles, data cables, chargers, etc., so far, there are two types of structures: paper and paper-plastic composite. It is possible that by 2025, 50% of the world’s degradable compostable bag packaging pouch can be realized. The reason why it cannot be popularized on a large scale is that its molecules are not stable enough and will not have a good moisture-proof effect in a humid environment. Therefore, most of the current bio-degradable compostable packaging bags pouch are mainly used to pack some dry products that are not afraid of moisture.

This is the latest new fully biodegradable compostable food packaging pouch environmental friendly material. Has been used by many super companies pursuing environmental protection.

Such as Accorhotels and McDonald.

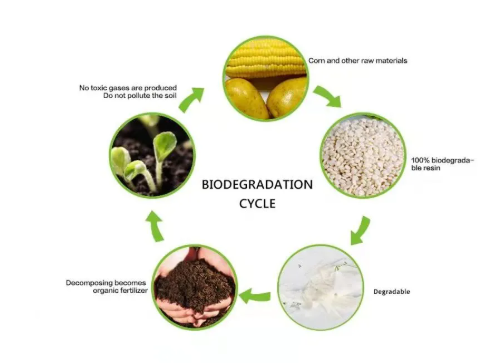

Here are some introduction about P-L- A (polylactic acid) one of Biodegradable and compostable bag packaging pouch material

PLA: Polylactic acid (PLA) is a brand-new biodegradable material made from starch raw materials proposed by renewable plant resources (such as corn).

Starch raw materials are saccharified to obtain glucose, which is then fermented by glucose and certain strains to produce high-purity lactic acid, and then a certain molecular weight polylactic acid is synthesized by chemical synthesis. It has good biodegradability.

After using, The biodegradable and compostable bag packaging pouch

can be completely degraded by microorganisms in nature, and finally carbon dioxide and water are generated without polluting the environment. This is very beneficial to environmental protection and is recognized as an environmentally friendly material. Ordinary plastics are still treated by incineration and cremation, causing a large amount of greenhouse gases to be discharged into the air, while polylactic acid plastics are buried in the soil to degrade, and the carbon dioxide produced directly enters the soil organic matter or is absorbed by plants, which will not be discharged into the air, and will not cause the greenhouse effect.

Here is a common all-biodegradable compostable bag packaging pouch:

NO1: PLA+PLA is currently one of the most environmentally friendly materials with the shortest degradation time. Outer Pla can be printed by different colour ( the ink will be the food grade too)

NO2: PLA+KRAFT. The two environmentally friendly materials are compounded into full biodegradable packaging, and the innermost PLA structure directly touches the product. The outer layer of kraft paper is beautiful and environmentally friendly. Is currently the most popular combination.

More PLA+KRAFTT pouches for your reference. It fits with all kinds of bags too.

Conditions of use and time of use(Biodegradable and compostable bag packaging pouch

):

Temperature -18 degrees -45 degrees, luminosity is 50% low light, can be used for 12 months, meet normal merchandise sales

Precautions:

Do not store in the sun or in a dark and humid place (will shorten the shelf life)

Advantages and disadvantages(Biodegradable and compostable bag packaging pouch

):

Advantages: Generate CO2+H2O after complete degradation

Disadvantages: This material has poor moisture resistance and barrier properties, and is only suitable for packaging products that do not require high moisture resistance and barrier properties.

Degradation conditions:

Biodegradation needs to meet three conditions: moisture, temperature, microorganisms, and under the conditions of industrial composting, the three conditions are different in a certain environment, which affects the speed of degradation.

Biodegradation conditions of industrial compost:

1. The temperature is 58~60℃,

2. Moisture content is 90~95%,

3. Enough microbes and bacteria, multiply and decompose.

4. The film bag can be completely decomposed in 3~6 months.

5. This sample is completely degraded to CO2+H2O within 1 year under the conditions of industrial compost degradation.

Household composting conditions(Biodegradable and compostable bag packaging pouch

):

1. Temperature 28~30℃

2. Humidity 90-95%

3. Under sufficient microbial environment

4. Household compost degradation period is 360 days

5. Under the condition of household composting, this sample will become brittle for 12-18 months at room temperature, and will be brittle and decompose the fragments and powder, but will not disappear. It must be completely degraded to CO2+H2O under industrial composting conditions.

The technical data sheet of the listed products

| ITEM | UNIT | REFERENCE INDEX |

| Appearance | — | White or yellow cylindrical granules |

| Particle Diameter | mm | 2~4 |

| Density | g/cm3 | 1.25±0.05 |

| Monomer | % | ≤1 |

| Melt Index(190℃ 2.16kg) | g/10min | 1~30 |

| Glass Transition Temperature | ℃ | 58~60 |

| Melting Point | ℃ | ~160 |

| Tensile Strength at Break | MPa | ~50 |

| Tensile Modulus | GPa | 3.5~6.0 |

| Impact Strength | J/m | 10~13 |

| (ITEM) | Unit | PP | GPPS | PET | PLA |

| (Density) | g/cm3 | 0.90—0.91 | 1.04—1.09 | 1.3—1.4 | 1.25 |

| (Melt Index(190℃ 2.16kg)) | g/10min | 0.2—20 | 1.5—30 | — | 1—30 |

| (Tensile Strength) | MPa | 29.6—35 | ≥58.8 | ≥60 | ≥50 |

| (Elongation at break) | % | 200—700 | 1.0—2.5 | 30—70 | ≥5 |

| (Transmittance) | % | 85—88 | 88—92 | 90—92 | 90—95

|

Post time: Sep-13-2021